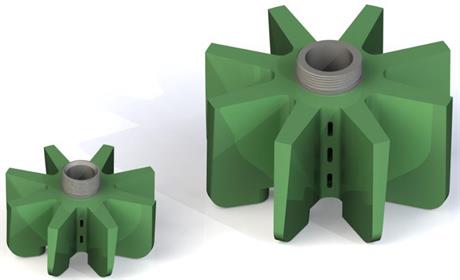

The heart of any flotation machine is the impeller.

The lower part of the impeller is especially flexible so that it can be started after a plant shut down. The lower parts are flexible and will then bend and enable startup without damage to the parts. The impeller design creates an low pressure sone near the air openings, which allows the impeller to suck air by itself. This does not provide enough air for good flotation, but it reduces the need for extra air supply.

Together with the impeller the stator is the most important part in the floation machine. We have designed this stator based on 45 years of experience. This stator offers excellent air dispergence and distribution of air. This stator and impeller gives maximal agitation and air dispergence in relation to air consumption.

It is made of specially picked materials and it has many years lifespan.

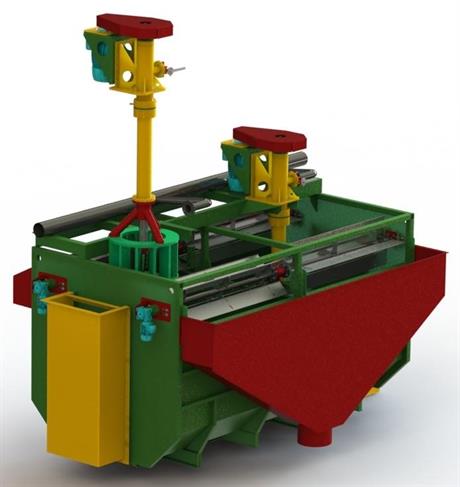

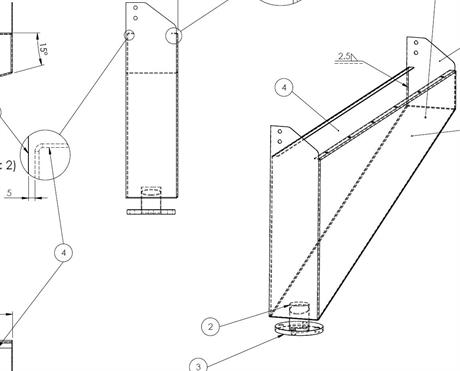

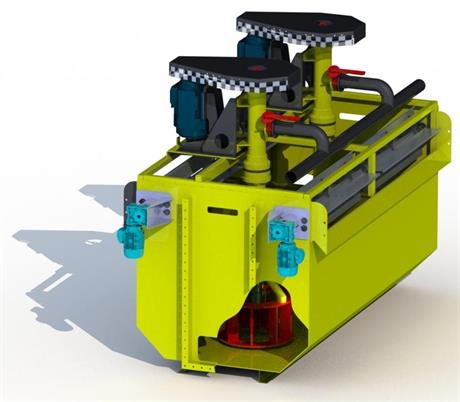

Complete mechanism

Complete mechanism

Complete mechanism

The special design makes it a perfect retrofit unit for existing flotation machines. We can assist in adapter design in case it is necessary.

Capiros mechanism is inserted top down into the cellbox. This makes it possible to replace a mechanism in a few minutes if you have an above crane.

In advance you prepare the new mechanism before you lift out the old one from the cell. Insert the new and hook up electrical and air supply after first having bolted it to the cellbox.

This allows for mechanism replacement while the process is running. Reducing feed and adding more water would be beneficial in order to avoid to much settling in the cell.

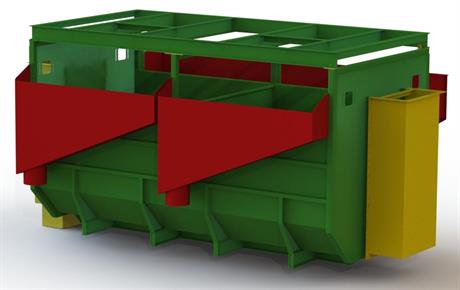

Flotation machines up to 100 m3

Flotation machines up to 100 m3

We offer complete machines of many sizes with volumes up to 60m3 for each mechanism