How to make your own Greenland paddle step by step

By Anders Thygesen

Materials for paddle making

When you've decided to make a paddle, the first step is to acquire good materials. Luckily these are easy to acquire here in Norway. The choice is usually between spruce and pine, which are both acceptable. The Greenlanders preferred pine, which could be found as driftwood along most of the coast. Personally, I prefer spruce. Most importantly, spruce is light. Spruce paddles can weigh as little as six or seven hundred grams, which I appreciate. When that's said, spruce is not the most durable wood. Pine is more durable but unfortunately also heavier! If durability is important, consider using spruce with reinforced blades - more about that later. I'll also mention that a spruce paddle, even when worn, works fine. A Greenland paddle of spruce can last a lifetime.

Your lumber should be without knots. Small knots are unimportant, but large knots can weaken the paddle and make planing difficult. The wood should also be straight, without internal tension. Tension in the wood tends to occur most often in compression wood and in wood that grows slowly, such as mountain spruce. Wood that grows excessively fast can also be problematic - it has a tendency to warp and be unstable, even rather weak. Closely spaced tree rings make the paddle durable, but also unnecessarily heavy. Try to find a piece of wood with moderately spaced rings.

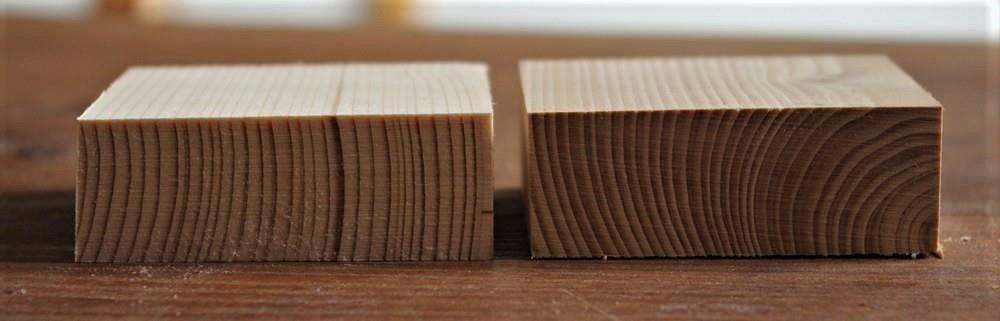

Two wood pieces with vertical rings. The left one is moderately grown, and excellent for making paddles. The wood on the right contains a lot of compression wood, and is therefore unsuitable. It would produce a heavy paddle that would warp.

The rings can be oriented either vertically or horizontally. Vertical rings are the most traditional, and a safe choice if making a paddle from whole wood. Horizontal rings work fine, but require more of the wood in terms of the absence of internal tension, and should be laminated to avoid having the wood warp. Personally, I almost exclusively use horizontal tree rings. This is because I tend to laminate all my paddles, and I have good access to fine materials with horizontal rings. In this article, however, we shall look at building a paddle from whole wood with vertical.

Go to your local timber store and inspect the selection available. Your finished paddle should be as long as the height of the final joint of your up-stretched arm. This is between 210 and 230 cm (6'10''-7'6'') for most people. Your selected piece of wood should therefore be equally long, or contain a piece that's that long and fairly straight and free of knots. 2x4 inches is a tempting size to look for, but it can be hard to find such a piece without.

If you use a wide plank as your starting point you should cut out a piece that's 4 to 5 inches wide. To make sure the wood is sufficiently dry, you can put it somewhere warm and dry for a few weeks or months, such as in your living room, or on a floor with heating cables. You can often find planks that are 1.5 inches thick and of varying width. It can be worth looking here. In the picture below I've found a plank that's 1 1/2 by 9 inches, 2.5 metres long. It cost 100 NOK ($15) and can be used to make 2 good paddles.

The work begins

We now have a piece of lumber to make the paddle from. It should be about 35 mm (1 3/8 inches) thick. We start by drawing the outline of the paddle on the wood. First, draw the central line, then measure out the following distances: Length of paddle = height of the final joint of your up-stretched arm. Mark this distance on the plank to be worked. Then draw a line that splits it down the middle.

The breadth of the shaft should equal the breadth of your shoulders plus the breadth of two fists. Mark the shaft on the wood. Finally mark up the transition between the shaft and the blade, which runs about 3 cm (1 1/4 inches) on each side of the shaft. The blade's breadth is 9 cm (3 1/2 inches) at the widest point and 4 cm (1 9/16 inches) at the thinnest. The shaft is 2.6 cm (1 inch) wide. Try to draw a curve in the transition from shaft to blade and a small curve on the outer end of the blade.

Now start sawing. A jigsaw or band saw will be fine, but it's feasible to saw by hand too. Then plane the wood, carefully following the lines you drew earlier so that all surfaces are at 90-degree angles compared to the surface you drew on. A small block plane or spokeshave are good tools for this.

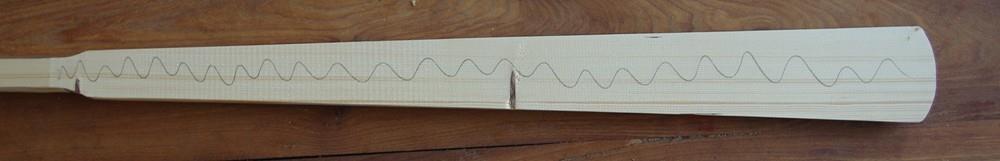

When this is done you can draw up the lines for planing the blade, as shown in the picture below. The distance between the lines should be about 5 millimetres (3/16 inches). Use a permanent marker for beefy lines.

Plane the blade from the outer edge of the shaft to the line at the end of the blade. You can use a large block plane or electric.

At last, it's time to plane the blades themselves. First, draw up a central line or lines over the entire blade. This is to avoid planing the blade too thin anywhere. There should be pencil marks remaining when you're done!

Wedge the oar tightly in a workbench, or fix it in place on a solid table with a pair of large clamps. Put your thigh against the paddle blade, and start planing away the wood between the middle of the blade and the line on the side of the.

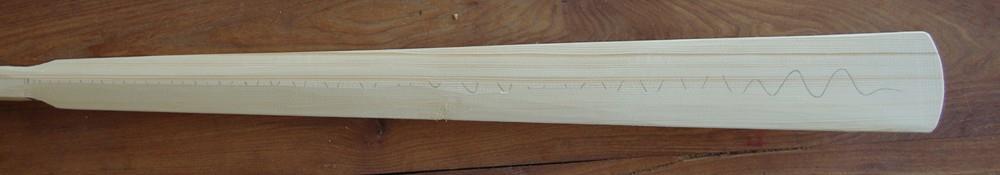

When you're done the paddle should look like this:

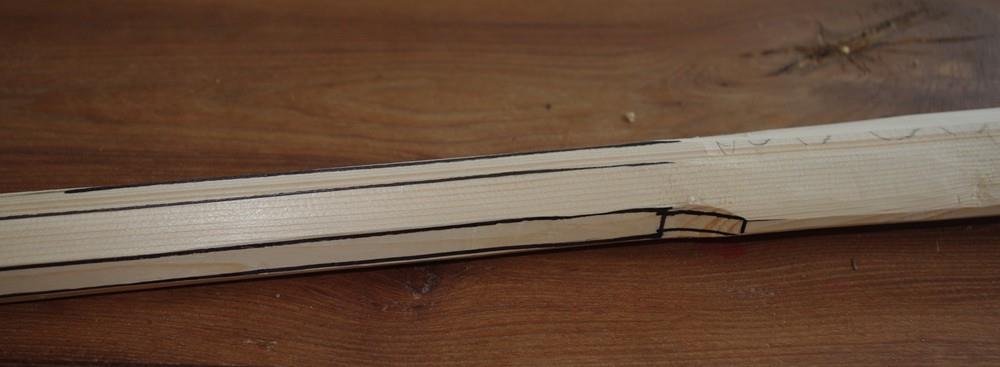

Now mark up the shaft as shown in the picture. There are four surfaces, and each one should be divided into 3 equal parts by two lines.

Plane away the material between the lines, so that the shaft becomes like this.

Use a spokeshave for this. Then round off the eight edges, so that the shaft becomes 16-sided. Then round off the remaining edges until the shaft is oval. One last important thing is left now - the transition between shaft and blade. Use a sharp knife, and shape it as shown on the photo below.

When you're done, the transition should look like the one below.

Finishing

The paddle's finally done, but one important thing is left - the finish. Start by sanding the paddle. First grain size 60, then 80, 120, and finally 240. Feel free to moisten the paddle after the last round and sand it again. If you want to colour the paddle, you can use a wood stain that's soluble in water or white spirit, and apply this before the surface treatment. The paddle pictured here has received one coating of mahogany-brown wood stain, which I've watered down to get a lighter shade.

Now the paddle needs a surface treatment. You can use a lot of different substances from varnish to oil, but here we'll use linseed oil. Buy a bottle of raw cold-pressed linseed oil (in Norway Biltema has a cheap and usable one). Heat some oil to about 60°C (140°F) in a kettle and apply two or three coats to the paddle. It may be useful to put the paddle ends in a box of oil overnight. Turn it so that both paddle ends are thorough saturated.

The best approach now is to let the paddle dry outside, exposed to sun and wind for a few weeks. Once it's dried, you can give it a thin coat of boiled linseed oil. This provides a seal that gives the paddle a hard, water-repelling surface. Let this oil dry for a few days too, preferably outside. You can use the paddle the way it is now. It should last for several years without maintenance. If the ends start getting worn, you can apply some more boiled linseed oil on the exposed. The Greenlanders usually reinforced the ends and edges of their paddle with whalebone. If you want the paddle to look traditional, you can take some white paint and paint the outer ends of the paddle.

The only thing left for me to do is to wish you good luck. Hopefully, you've now made a paddle with simple materials, which can give you lots of joy for the rest of your life!

Here's a small selection of different paddle blades. There are many ways to make paddle blades, with or without reinforcement.